1 / 4

132KV 1 * 800sqmm koppar XLPE isolerad strömkabel

| Model No. : | N2XSF2Y |

|---|---|

| Brand Name : | HUAYUAN YONGTONG |

| Application : | Construction |

Beijing, Beijing, China

- Distributörgrossist

- Tillverkare

- OEM -tjänst

- Plattformscertifiering

- Video

Produktbeskrivning

TECHNICLA DATABLAD FÖR132 kV 1C800 SQmm POWER CABLE

| NO. | ITEM | UNIT | DATA |

| 1 | Name of Manufacturer: | Beijing Huayuan Gaoke | |

| Cable Co.,Ltd. | |||

| 1.2 | Country of Manufacturer: | China | |

| 2 | Which type of manufacturing process viz. Continuous Catenary Vulcanisation (CCV) or vertical Catenary Vulcanisation system (VCV) or horizontal MDCV will be used to ensure circularity and concentricity of the extruded layers around the conductor. | VCV | |

| 3 | Type of Cable: | Cu/XLPE/Al/MDPE | |

| 4 | Rated nominal voltage | kV | 76/132 |

| 5 | Rated Maximum voltage | kV | 145 |

| 6 | Nominal cross-sectional area of Conductor | Sq.mm | 800 |

| 7 | Conductor | ||

| 7.1 | Material | copper | |

| 7.2 | Shape & formation | segment & in 5 segment for into circular | |

| 7.3 | Diameter of conductor | mm | 34 |

| 7.4 | Dia.Of Single Wire/Number of strands | mm | 3.5/88 |

| 8 | Conductor Screen | ||

| 8.1 | Material | Semi-conductor nylon tape +Super slippery Semi conductive XLPE Material | |

| 8.2 | Thickness of semi conducting tape | mm | 0.12 |

| 8.3 | Thickness of seim-conductot XLPE | mm | 1.5 |

| 8.4 | Diameter of Sime-conductor(Approx.) | mm | 37.4 |

| 9 | Insulation | ||

| 9.1 | Material | super purity material/XLPE | |

| 9.2 | Insulation Thickness(Min.Avg.) | mm | 18 |

| 9.3 | Diameter of Insulation(Approx.) | mm | 73.4 |

| 10 | Insulation Screen | ||

| 10.1 | Material | Super slippery Semi conductive Material | |

| 10.2 | Insulation Screen Thickness(Approx.) | mm | 1.2 |

| 10.3 | Diameter of Sime-Insulation(Approx.) | mm | 75.8 |

| 11 | Swellable type water blocking semi –conducting tape | ||

| 11.1 | Material | semi conductive water swellable tape | |

| 11.2 | Approximate thickness | mm/mm | 2×2.0 |

| 11.3 | Diameter of Swellable tape (Approx.) | mm | 82.8 |

| 12 | Metallic Sheath: | ||

| 12.1 | Material | Corrugated Aluminum | |

| 12.2 | Constructional feature. | Corrugated | |

| 12.3 | Thickness of the sheath (Radial) | mm | 2 |

| 12.4 | Diameter of the cable across the metallic sheath(Approx.) | mm | 95.8 |

| 13 | Anti-corrosion layer | ||

| 13.1 | Material | asphaltum | |

| 13.2 | Thickness of the anti-corrsion | 0.2 | |

| 13.3 | Diameter of the cable Anti-corrosion(Approx.) | 96.2 | |

| 14 | Outer Shealth | ||

| 14.1 | Material | MDPE | |

| 14.2 | Outer Sheath Thickness(Nominal) | 4.5 | |

| 14.3 | Over Diameter(Approx.) | 105.2 | |

| 15 | Conductor Weight | kg/km | 7156 |

| 16 | Total Cable Weight (Approx.) | kg/km | 14290 |

| 17 | Minimum Bending Radius | ||

| 17.1 | During Installation | mm | 2100 |

| 17.2 | Installed | mm | 1700 |

| 18 | Maximum Pulling Tension | ||

| 18.1 | Of Conductor | kN | 56 |

| 18.2 | Of Metallic Sheath: | kN | 56 |

| 19 | Continuous current rating under the specified installation and operating conditions. Conductor temperature 90° C . Ground temperature 35° C and depth of laying 1500 mm | ||

| 19.1 | In Air | Amp | 1,281 |

| 19.2 | In Ground | Amp | 842 |

| 19.3 | In pipeline | Amp | 815 |

| 20 | Maximum value of electric stresses at the conductor screen | kV/mm | 6.03 |

| 21 | Maximum value of dielectric stress at the insulation | kV/mm | 3.07 |

| 22 | Short circuit capacity of conductor for 1/2/3 second assuming conductor temperature of 90 ° C prior to short circuit and 250 ° C during short circuit | ||

| 22.1 | 1.0 Secs | kA | 114.8 |

| 22.2 | 2.0 Secs | kA | 81.5 |

| 22.3 | 3.0 Secs | kA | 66.8 |

| 23 | Short circuit capacity of metallic sheath for 1/2/3 second at screen temperature of 75 ° C prior to short circuit and 200 ° C during short circuit | ||

| 23.1 | 1.0 Secs | kA | 52.4 |

| 23.2 | 2.0 Secs | kA | 38.1 |

| 23.3 | 3.0 Secs | kA | 31.5 |

| 24 | Ionization factor at 50 Hz. (Tan Delta) | 0.0008 | |

| 25 | Sheath voltage under maximum operating conditions assuming all circuits connected | kV per km | 0.105 |

| 26 | TTST | ||

| 26.1 | Maximum D.C. resistance of conductor per km. at 20 degree C. | Ohm | 0.0221 |

| 26.2 | Maximum A.C. resistance of conductor per km. at 90 degree C. | Ohm | 0.0289 |

| 26.3 | Equivalent star reactance per km. of 3-phase Circuit at 50 Hz. | Ohm | 0.127 |

| 26.4 | Maximum electrostatic capacitance per km. of cable. | μF | 0.19 |

| 26.5 | Partial discharge at 2 Uo 1.50 Uo | pc | ≤ 5 |

| 26.6 | A.C. Enduring Test voltage 2.5U0/ hours | kV/mim | 190/30 |

| 26.7 | D.C.Out sheath Enduring Test voltage | kV/mim | 25kV/1min |

| 26.8 | Impulse test voltage | kV | 650 |

| 27 | Approximate drum dimension (dia & width) | mm/mm | 3500*2400 |

| 28 | Maximum length of cable in a drum (Metres) | m | 550 |

| 29 | Minimum length of cable in a drum (Metres) | m | 500 |

| 30 | Approximate gross weight of cable in a drum (MT) | TON | 8.3 |

| 31 | Expected Cable life. | Year | 30 |

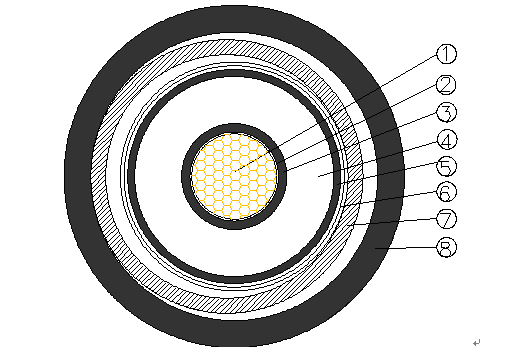

Kabelstorlek och uppbyggnad av sektioner

XLPE 76/132 (145) kV 1 × 800 mm 2

|

Construction |

Thickness(mm) |

Diameter(mm) |

|

1--Conductor |

|

34.0(+0.5,-0.5) |

|

2--Semi-conducting tape |

0.12 |

34.4 |

|

3--Conductor screen |

1.5 |

37.4 |

|

4--XLPE insulation |

18.0 |

73.4(+1.5,-1.0) |

|

5--Insulation screen |

1.2 |

75.8 |

|

6--Semi-conducting bedding tape |

4.0 |

82.8 |

|

8--Corrugated Al sheath (including asphalt) |

2.0 |

96.2 |

|

9-MDPE outer sheath (including graphite) |

4.5 |

105.2(+3.0,-2.5) |

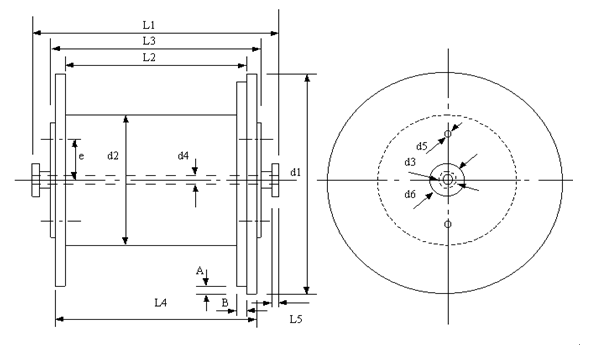

Trumma

d1: 3500mm

L1: 2400mm

500m per trumma

H: 3500mm

L: 3500mm

W: 2400 mm

Wight: 1000 kg

Avancerad tillverkningsutrustning

Advanced Testing Utrustning

Företaget introducerade världens avancerade nivåledning och kabelproduktion och provningsutrustning, såsom DV-6E-spektrumanalysator, online-mikroporrenhetstester, etc.

Avancerad testutrustning garanterar högkvalitativ produktion

paket

Vår ära

Vi fick tillit och pris från alla kunder av enastående kvalitet och gott rykte. För att tillhandahålla förstklassiga produkter och service för samhället är jakten på staber i vårt företag för alltid. Serviceavdelningen efter försäljning tillhandahåller en serie före försäljning, försäljning och eftersalg, vilket löser de bekymmer som finns bakom kunderna och ger fullständig och snabb service för kunderna. Kundernas tillfredsställelse är den bästa avkastningen för personalen i vårt företag.

1.132kv kabel 2.High Voltage Power Cable 3.Hv Xlpe Cable 4.Building Wire 5.Electrical Cable Wires 6.110kv Cable

Beijing, Beijing, China

- Distributörgrossist

- Tillverkare

- OEM -tjänst

- Plattformscertifiering

- Video

Skicka din förfrågan till denna leverantör